Structural Stainless-Steel Barriers - Riverside, CA

Market - WATER TREATMENT

SERVICES RENDERED

-

Provided fabrication based on completed design drawings for customer will call.

PROBLEM-SOLVING & ADAPTABILITY

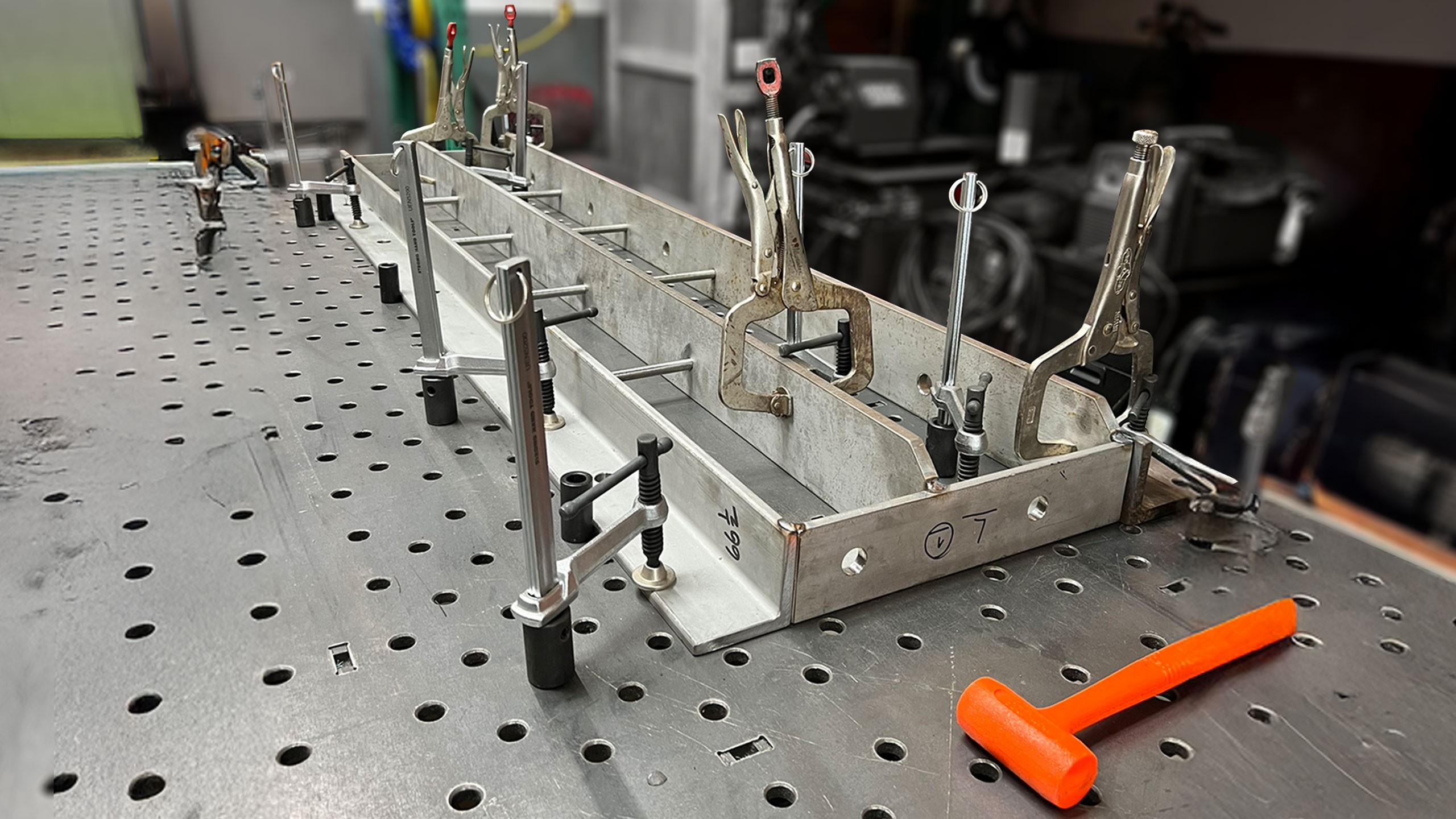

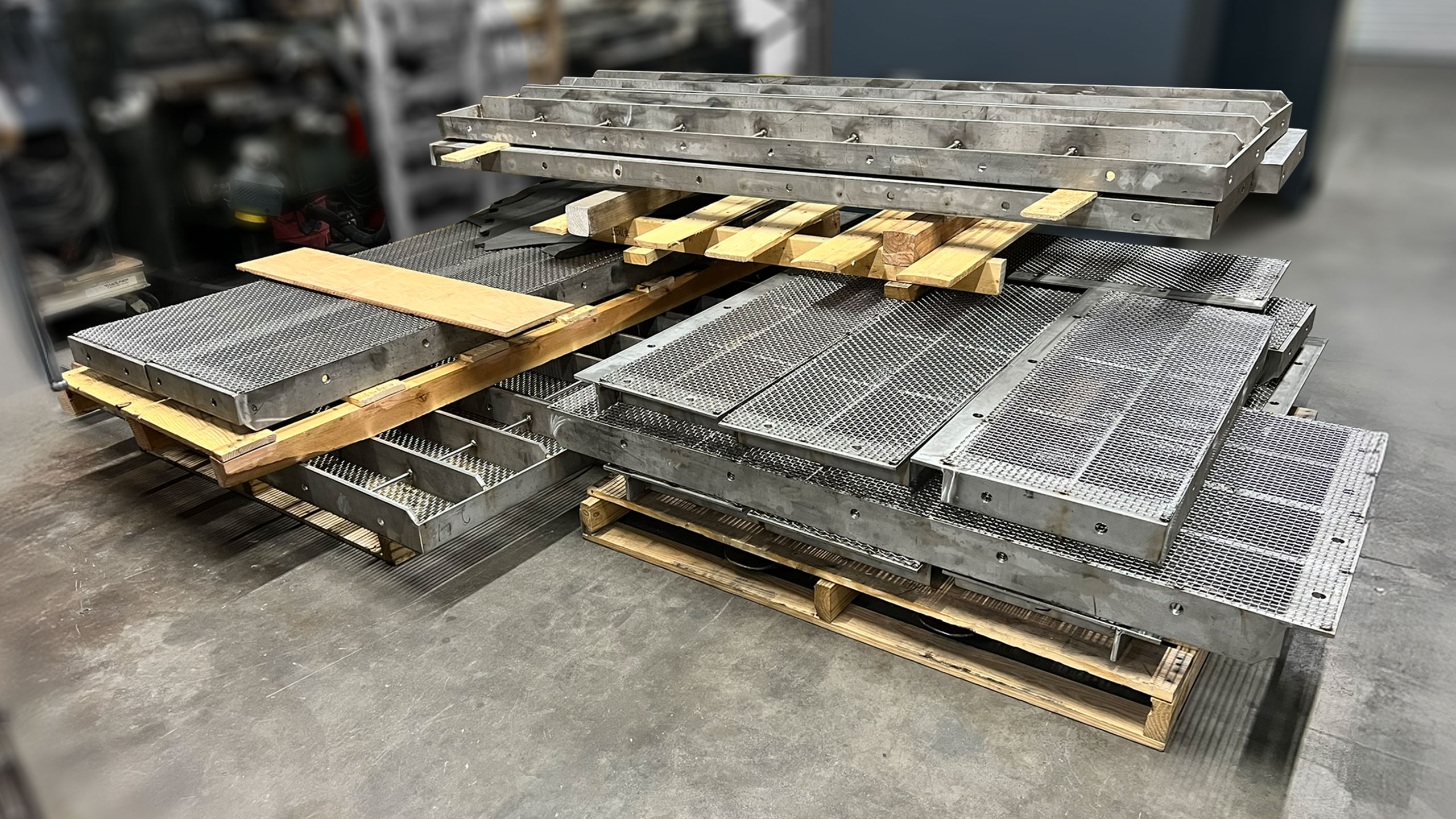

We utilized multiple computer aided material preparation processes to expedite the fabrication process. Fiber laser cutting, CNC milling, and CNC saw cutting.

Fabrication

Completed the project on budget

Project Summary

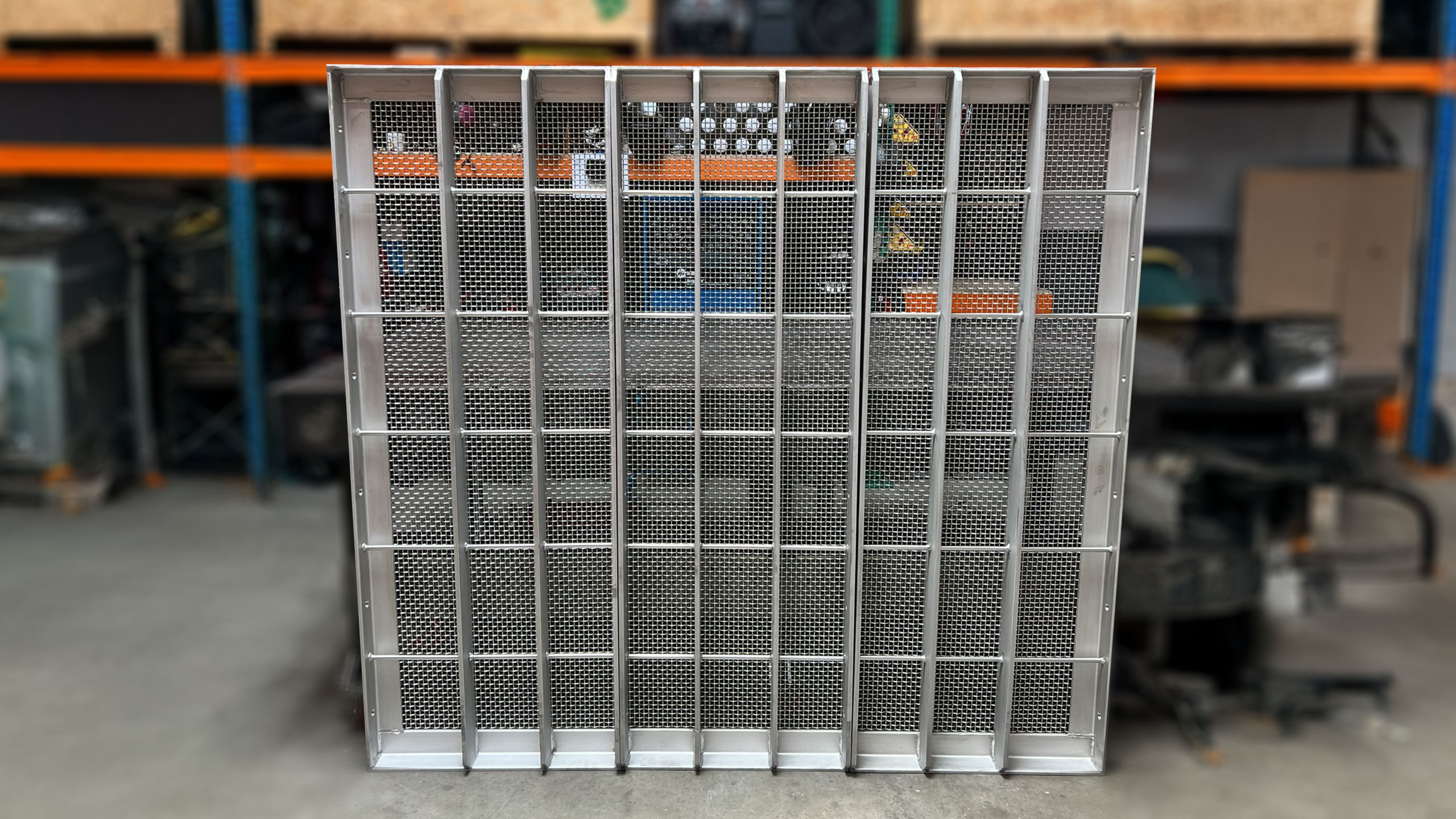

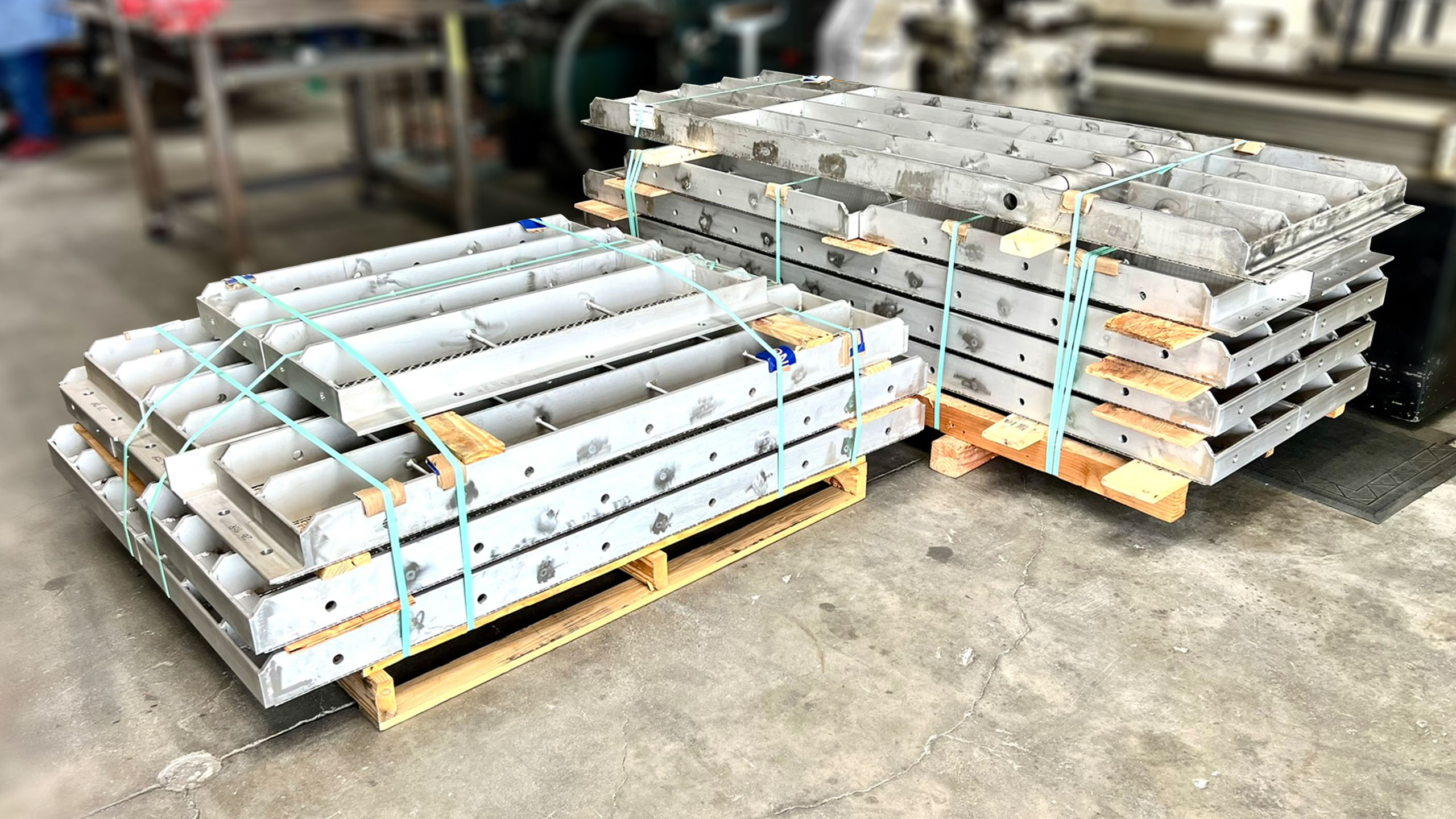

For this project, MWD provided complete drawings and fabrication specifications. During material procurement, we used fiber laser cutting and CNC milling to precisely cut all components for 21 Panels. FCAW (Flux-Cored Arc Welding) was employed for welding the structural elements, while GTAW (Gas Tungsten Arc Welding) was used to attach the wire mesh. After fabrication, all assemblies were sent for pickling and passivation to ensure proper decontamination of the welded areas.

- CONTRACTOR: Owner

- CLIENT NAME: Metropolitan Water District of Southern California

Client Feedback

Demel Fabrication delivered a highly efficient and professional solution for our in-suite egress stair. From concept design through installation, their team was responsive, detail-driven, and adaptable. The prefabricated kit approach minimized onsite disruption and helped us stay on schedule. Their ability to meet code, coordinate with multiple teams, and execute cleanly on-site was impressive.